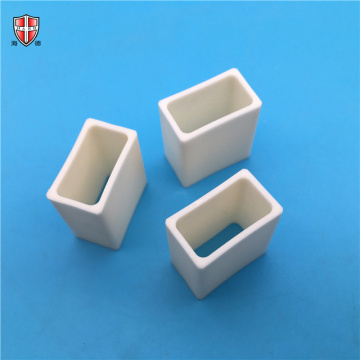

injection moulding alumina ceramic square thin tube pipe

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Terms of Trade: | FOB |

| Min. Order: | 1 Piece/Pieces |

| Delivery Time: | 15 Days |

| Packaging: | Customized |

|---|---|

| Brand: | Hard |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | Guangdong,China |

| Supply Ability: | 1,000,000 pcs/Month |

| Certificate: | SGS |

| Port: | Shenzhen |

Basic Info

Model No.: Al2O3 428

Click on the follow link to find out more information: https://www.hardcm.com/alumina-ceramic-tube/

Company Info

- Company Name: Dongguan Haikun New Material Co., Ltd.

- Representative: ZHOU SHENGBIN

- Product/Service: Alumina Ceramics , Zirconia Ceramics , Silicon Nitride Ceramics , Macor Ceramic , Aluminum Nitride Ceramic , Other Ceramic Materials

- Capital (Million US $): US$500,000

- Year Established: 2007

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 81% - 90%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: 5

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: 5F, 3BLD, SHIDAIZHIHUI, 159Luwusanlian Rd., Changping, Dongguan, China 523587

- Contact Person: Mr. Watson Lin

- Tel: 86-0769-81182989

Premium Related Products

Other Products

Hot Products